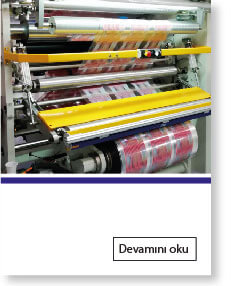

Our Lamination Process

The process of turning two or more materials into a new material by applying heat and pressure with the help of an adhesive is called "Lamination" such materials are called "Laminate". Care is taken to ensure that each film to be used as a minimum thickness sufficient for the purpose.

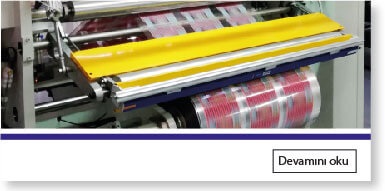

Solvent Free Lamination

The laminator applies the glue. Combines two layers of material to create flexible packaging lamination. There is no solvent to come out of the adhesive there is no need for upper ovens to dry the adhesive agent. The two materials are combined, rolled up in a roll, and the adhesive agent is allowed to cross-link for a certain period before moving on to the next production step. For products that will come into contact with food, the solvent-free lamination technique is the most preferred type worldwide.

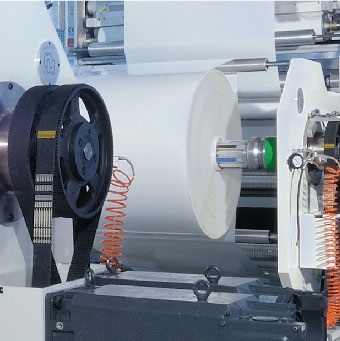

Solvent Lamination

Depending on the type of treatment to which the packaged product will be subjected, pasteurization, a solvent-based adhesive is used. The solvent evaporates as it passes through the drying tunnel. The resins that make up the adhesive are dissolved in organic solvents, which may be one or more of the following: ethyl acetate, ethanol, isopropanol, methyl ethyl ketone (2-butanone).